BASF 60cm (24") Red PVC Chemical Full Arm Gauntlet

- Product Code: GPVCC600

- Availability: IN STOCK

-

£5.00

Lowest price

EXCL VAT - £6.00 inc. VAT

| 1+ | 6+ | 36+ | 60+ |

|---|---|---|---|

| £7.44 (£6.20 ex. vat) | £6.94 (£5.78 ex. vat) | £6.47 (£5.39 ex. vat) | £6.00 (£5.00 ex. vat) |

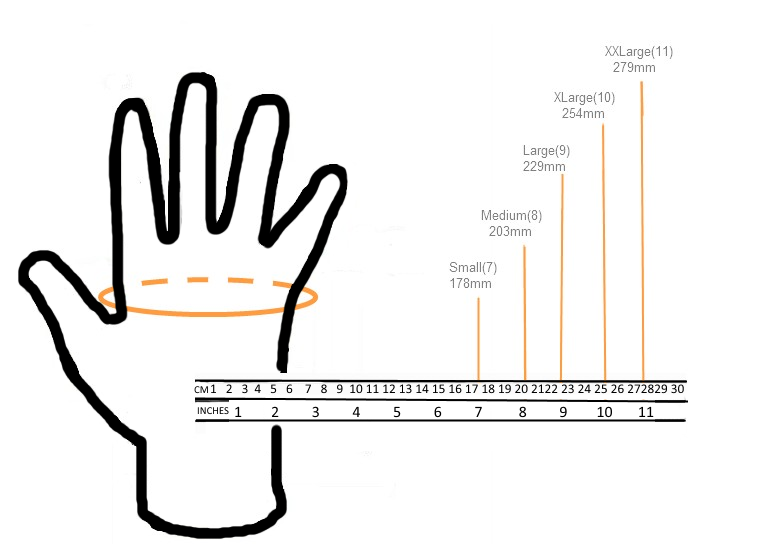

| Glove Size | Qty |

|---|---|

| XLarge (10) |

BASF DeltaPlus Chemical Protection Red PVC 60cm Gauntlets.

Made using a non-phthalate plasticizer Hexamol® DINCH®

Safe for sensitive applications

Complies with REACH regulations

Environmentally Friendly

Suitable for Food contact applications

Specially formulated to give high resistance to oils, chemicals and petrol derivatives.

A very tough PVC coating gives high resistance to abrasion.

Flared gauntlet style for ease of removal.

Chemical PVC. PVC on cotton jersey lining. Length: 60 cm. Thickness: 1,30 mm.

Glove: 100% PVC vulcanized and coated on cotton jersey support.

Thickness : 1,20 - 1,40 mm

Typical applications: General handling of chemicals.

Size available: 10

TECHNICAL DETAILS

Mechanical test data in accordance with EN 388 2016

Abrasion Resistance Level 4

Cut Resistance Level 1

Tear Resistance Level 3

Puncture Resistance Level 1Resistance to cutting by sharp objects (TDM EN ISO 13997) X

BASF DeltaPlus Chemical Protection Red PVC 60cm Gauntlets.

Made using a non-phthalate plasticizer Hexamol® DINCH®

Safe for sensitive applications

Complies with REACH regulations

Environmentally Friendly

Suitable for Food contact applications

Specially formulated to give high resistance to oils, chemicals and petrol derivatives.

A very tough PVC coating gives high resistance to abrasion.

Flared gauntlet style for ease of removal.

Chemical PVC. PVC on cotton jersey lining. Length: 60 cm. Thickness: 1,30 mm.

Glove: 100% PVC vulcanized and coated on cotton jersey support.

Thickness : 1,20 - 1,40 mm

Typical applications: General handling of chemicals.

Size available: 10

TECHNICAL DETAILS

Mechanical test data in accordance with EN 388

Abrasion Resistance Level 4

Cut Resistance Level 1

Tear Resistance Level 2

Puncture Resistance Level 1

Chemical test data in accordance with EN 374

| Chemicals | BTT (min) | Class |

| 30% Sulphuric Acid | >480 | 6 |

| 98% Sulphuric Acid | 169 | 4 |

| Conc. Hydrochloric Acid | >480 | 6 |

| Acetic Acid | 135 | 4 |

| Xylene | 50 | 2 |

| Trichloroethylene | 24 | 1 |

Chemicals | BTT (min) | Class |

30% Sulphuric Acid | >480 | 6 |

98% Sulphuric Acid | 169 | 4 |

Conc. Hydrochloric Acid | >480 | 6 |

Acetic Acid | 135 | 4 |

Xylene | 50 | 2 |

Trichloroethylene | 24 | 1 |

The results are taken from the palm area of the gloves

These gloves are manufactured under an approved ISO9002 quality control system.

OTHER INFORMATION

Both new and used gloves should be thoroughly inspected before being worn to ensure

no damage is present.

Gloves should not be left in a contaminated condition if reuse is intended in which case

gloves should be cleaned as far as possible.

Washing of these gloves is not recommended.

Gloves may be washed with mild detergent then rinsed with clean water and allowed to dry,

ideally with some air movement.

Care should be taken when removing gloves to avoid any contaminant contacting bare skin.

STORAGE

Gloves should be ideally stored in cool dry conditions in the original package

and out of direct sunlight.

OBSOLESCENCE

When stored as recommended will not suffer change in mechanical properties

for up to 5 years from the date of manufacture.

Service life cannot be specified and depends on the application and

responsibility of the user to ascertain the suitability of the glove for

the intended use.

GENERAL

None of the materials or processes used in the manufacture of these products

are known to be harmful to the wearer.

PLEASE NOTE

The results of physical tests should help in glove selection,

however it must be understood that actual conditions of use cannot be

simulated and it is the responsibility of the end user and not the

manufacturer to determine glove suitability for the intended use.