HOW DO I PROTECT MY HANDS FROM HEAT & FLAMES?

EN 407: 2004

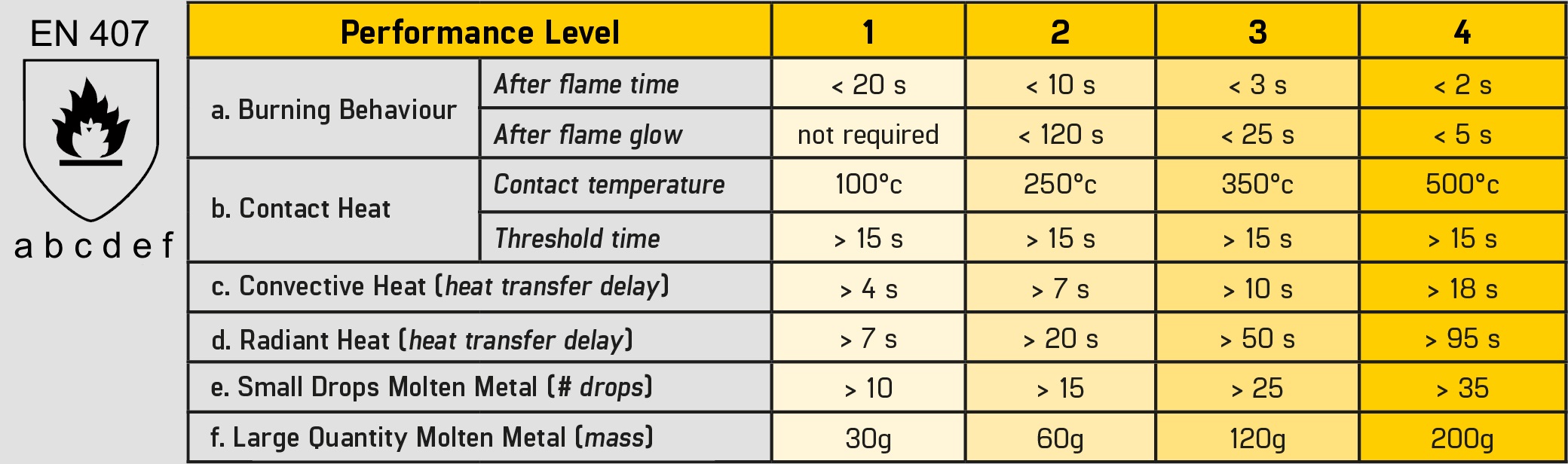

The European test for hazards relating to Heat, Flame and Molten Metal splash protection. If you work in an environment with these high risk hazards, the information from the test results of EN407 are an invaluable tool to help select the correct product for your protection.

There are 6 tests performed on the glove material and each is scored 0 to 4 depending on the test results. 4 being the maximum level of protection.

X means the glove hasn’t been tested for this hazard. 0 is a fail.

A large selection of gloves in our Heat Handling range are only tested for Contact Heat as this is the most common thermal hazard.

The six tests are for:

- Resistance to flammability / Burning behaviour (performance level 0 - 4)

- Contact heat resistance (performance level 0 - 4)

- Convective heat resistance (performance level 0 - 4)

- Radiant heat resistance (performance level 0 - 4)

- Resistance to small splashes of molten metal (performance level 0 - 4)

- f Resistance to large splashes of molten metal (performance level 0 - 4)

Here is an explanation of each test so you can use this information, linked to the EN407 score numbers for each product to help with your selection.

a. Resistance to Flammability / Burning Behaviour:

This test basically lets you know if your glove is resistant to naked flames.

The fingers of the glove are exposed to a small gas flame for 15 seconds. The Performance Level score is based on the length of time the glove continues to burn and glow after the flame is removed (see table above)

Also the glove seams must not come apart and the glove material can’t melt or drip.

b. Contact heat resistance:

This part of EN407 tells you how a glove insulates you from heat transfer- holding a hot object.

A calorimeter is placed on the inner surface of the glove material, whilst the outside surface is exposed to a hot probe which is set to a temperature ranging from 100-500°C

For Contact level 1 the temperature would be set at 100°C, the meter on the inside which at this point is at room temperature, must not rise by more than 10°C within 15 seconds for the material to pass.

For a glove to score 3 or higher for Contact heat, it must have first scored 3 for the Flammability test.

If it hasn’t it can only be given a maximum Contact heat score of 2 (250°C)

There are 4 temperatures tested for Contact heat protection test:

100°C (1), 250°C (2), 350°C (3), 500°C (4)

c. Convective Heat Resistance:

The glove must have passed the Flammability test first with a score of 3 or more to be able to be tested for convective heat resistance.

This test tells you how much protection the glove offers from heat transfer from a flame.

Similar to the 1st test, but the flame is more aggressive (80kW / m2), and different parts of the glove are tested.

The palm, back and cuff of the glove/gauntlet are exposed to the flame and the amount of time it takes for the temperature of the inner surface to be raised by 24°C noted. The time in seconds is then expressed as a number

1 to 4 if a pass is achieved.

| Performance Level | Seconds to raise temperature by 24°C |

| 1 | Under 4 |

| 2 | Under 7 |

| 3 | Under 10 |

| 4 | Under 18 |

d. Radiant Heat Resistance:

This is another test that can only be performed if a 3 or more is scored in the 1st test. (Flammability) This test indicates how the glove performs when exposed to a Radiant Heat source (2.5kW / m2), for example, stood near a furnace. This test is performed on the back of the glove, and indicates the time in seconds for the inner surface to rise by 24°C.

| Performance Level | Seconds to raise temperature by 24°C |

| 1 | Under 7 |

| 2 | Under 20 |

| 3 | Under 50 |

| 4 | Under 95 |

f. Resistance to Large Quantity of Molten Metal:

This test will give an indication of the protection provided if a large amount of Molten Metal was to spill on to the glove/gauntlet. PVC foil which acts as simulated skin is placed under the sample, and a weight of molten metal (eg iron) is poured onto the glove material, the total weight of molten metal to cause smoothing or pin holing across the simulated skin will give the performance score. The material will fail the test If a drop remains stuck to the sample, or the sample ignites or is punctured.

| Performance Level | Grams of Molten Metal |

| 1 | 30g |

| 2 | 60g |

| 3 | 120g |

| 4 | 200g |

Hopefully, that has helped explain the tests performed on the Heat Resistant glove we sell. Take a look at our wide range of heat handling gloves and gauntlets for protection from heat related injuries.